LNG

Solutions

ProSep’s high efficiency mixers and clean water technologies provide beneficial

solutions for a variety of LNG applications.

LNG Solutions

Explore ProSep

Aim

Osorb

Pretreatment

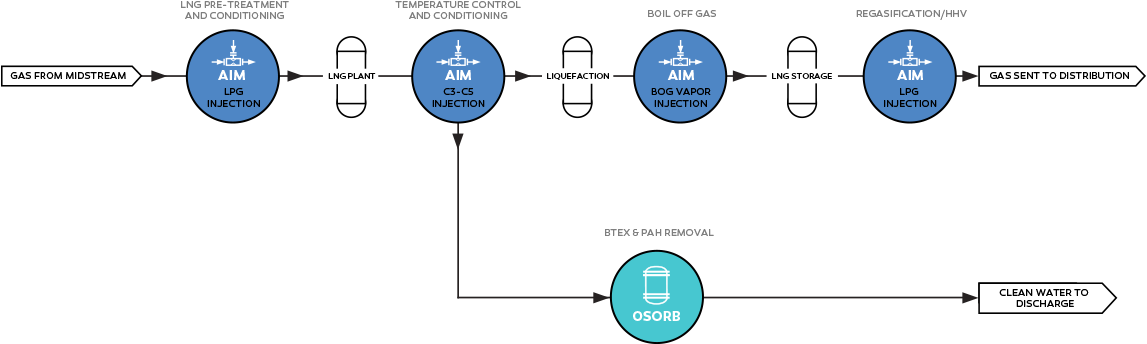

LNG processes demand very stringent natural gas specifications due to the risk of hydrate formation, mercury corrosion, acid gas liquefaction, etc., to ensure reliable operation of the LNG process.

ProSep’s AIM injection mixer has provided reliable, “best in class” injection / dispersion of LPGs into LNG natural gas feed streams to adjust lean gas composition as well as removing harmful heavy hydrocarbons and aromatic compounds with 80:1 LPG injection and 13:1 natural gas turndown ratio.

READ MORE

Compressor Suction Temperature Control

Start-up and shutdown of LNG facilities often requires recirculation of chilled gas, requiring compressor suction temperature control to improved system cooling efficiency.

ProSep’s AIM injection mixer has been evaluated to improve compressor suction temperature control over standard injection quills to prevent LPG overdosing.

READ MORE

Boil Off Gas

Even with the best insulation, LNG “boils off” during storage, loading and unloading, requiring LNG facilities and shipping vessels to capture and re-liquify those hydrocarbons for both environmental reasons and production efficiencies.

ProSep’s AIM injection mixer can be utilized to re-liquify BOG (boil off gas) at LNG facilities economically by optimizing injection into LNG streams where the cool temperatures re-condense the BOG to liquid state.

READ MORE

Regasification

There are a number of methods to regasify LNG for distribution at the destination point. Often, the resulting natural gas does not meet the local BTU requirements and needs to be upgraded with LPG fractions.

ProSep’s AIM injection mixer has provided reliable, “best in class” injection / dispersion of LPGs into LNG gas streams. CFD studies have demonstrated the primary and secondary LPG droplet breakup and dispersion promoting vaporization of significant volumes of LPG within short distances and at minimal pressure drop. These results have been validated in field operations, performing beyond expectation.

READ MORE

BTEX and PAH Removal

Particularly in offshore natural gas production for FLNG facilities, hydrate inhibitors are captured and reprocessed to be reused. Often time, heavy hydrocarbon components and BTEX report to the condensed water phase and need to be removed prior to overboard discharge.

ProSep’s OMS (Osorb Media System) utilizing Osorb media, a hydrocarbon adsorbent with a finite capacity that can be regenerated and reused, has demonstrated Best Available Technology (BAT), removing dispersed, emulsified and dissolved hydrocarbons, BTEX, PAH and WSOs.

READ MORE

HAVE A PROBLEM?

WE PROVIDE CLEAN SOLUTIONS.

Get AIM

If you have any questions or would like to inquire about our products or services, please use this button to contact us.